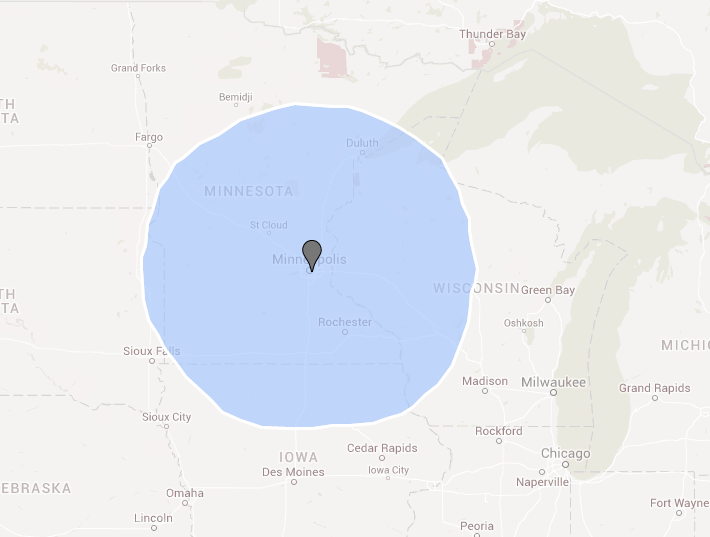

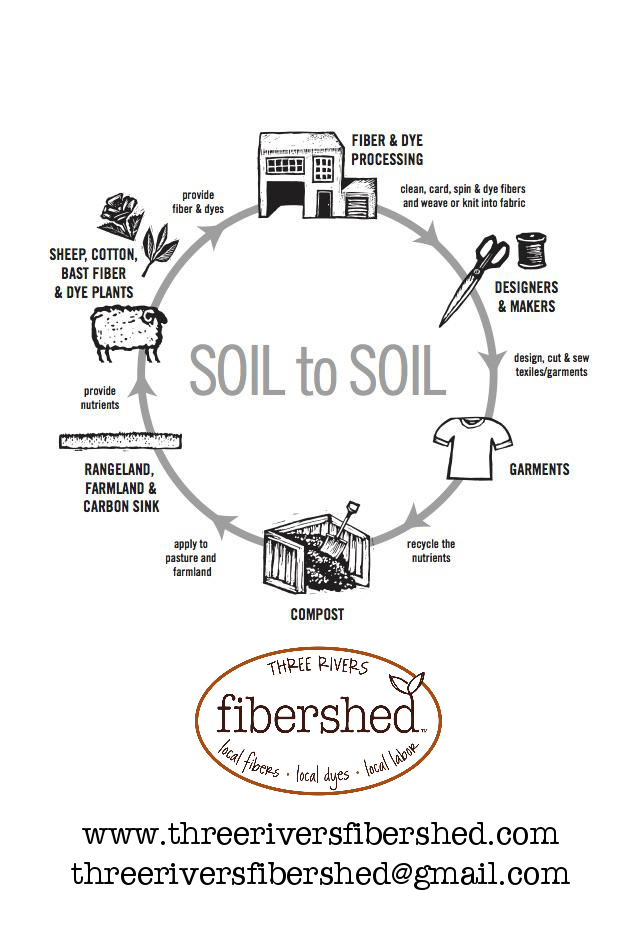

In August 2017, the Three Rivers Fibershed was awarded a micro-grant from the Northern California Fibershed. The focus of the grant centers on local producers who are isolated from resources and sustainable fiber production communities. By beginning to facilitate a network of producers who can find support within the Three Rivers Fibershed region, we hope to see the fiber aspect of their farm not only sustain them, but flourish. Producers will have support to work together to build fiber community that is making a profit off of their fiber products with ample access to avenues for markets. There will be a system of active, engaged local fiber producers working together to support the collective fiber community within our Fibershed, with some fiber producers willing to step into leadership roles to facilitate ongoing producer education around any of the challenges producers within our Fibershed are facing. This local producer support system will be built on a foundation where it is self-sustaining and self-regulating: what can local producers do for local producers? Empowering local producers to rely on each other for insight, guidance, and community building.

So what will the project look like and when is it happening?

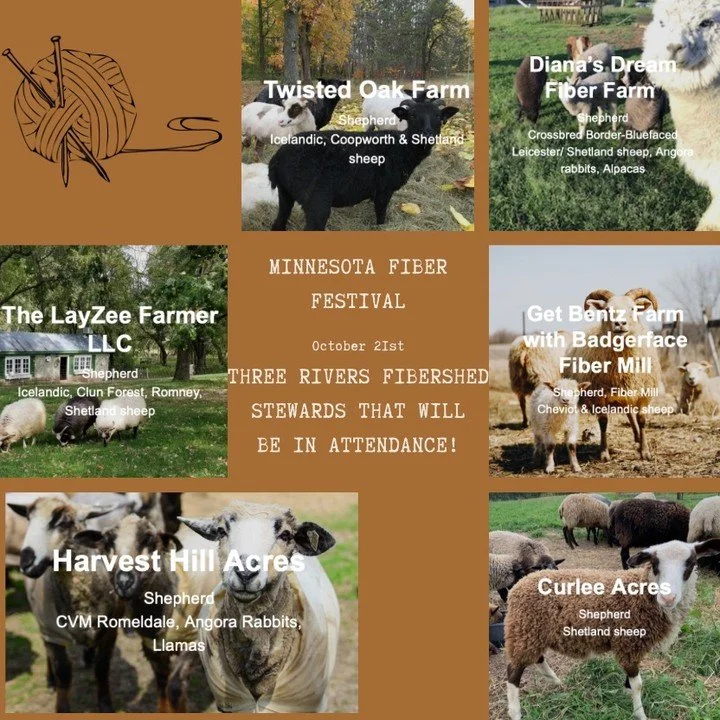

Three Rivers Fibershed will host and moderate two, in-person local producer workshops, offered at no cost to producers, with presentations by members of our fiber community. The first workshop on October 21, 2017, from 10am-5pm, will place a focus on our Fibershed’s collective strengths and challenges, marketing, branding, product presentation, telling the story of your farm and its fiber, and connecting with consumers and appropriate markets for optimal financial value. This workshop will be held at the farm of Lydia’s Flock in Harris, MN, lunch and workshop materials will be provided.

The second workshop, slated for January 2018, will focus on basic regenerative grazing practices to improve pasture health and sequester carbon, fleece health and shearing for high value fleeces, raising sheep for high value fiber, funding opportunities to grow your fiber operation, tracking fiber sales and expenses, and utilizing the MN State Colleges Farm Business Management program.

These workshops will be paired with one-on-one farm visits by our Producer Outreach Coordinator, who will, using a basis analysis for each producer’s fiber operations, assist producers in identifying internal and external successes and challenges of their individual operation. Information collected on farm visits will be used to determine the top five needs of producers in our area. By determining the top needs of our producers and providing free resources through our workshops, we believe a network of producers will be created. Within this network our producers can find support from their fellow producers and access to consumers within our Fibershed to sustain the fiber aspect of their farm.

Why focus on local producers?

Our project is designed to address the needs of aspiring and established local fiber producers within the Three Rivers Fibershed. Many of our producers are looking for a support system in order to sell value-added products while connecting with consumers who will pay a premium for locally grown and produced fiber as well as share information around small-scale sustainable shepherding–including but not limited to optimal grazing practices, finding a shearer, parasite management, insight as to which fiber animals flourish in our climate, and locating a mentor.

The need for this project is great. Within our Fibershed, the availability of in-person venues for sales and education around local fiber is significantly limited or unavailable, highly inconsistent or inappropriate for our producers. The second challenge comes through the lack of proper branding and packaging of local fiber to pique consumer interest, resulting in missed opportunities for producers to share the story of each local producer’s farm and fiber.

Producers have shared that local fiber is not seen as value-added and believe many consumers are unwilling to pay a premium for local fiber. There is a feeling that local producers are up against the commercial sheep industry in our radius who see wool as a by-product, resulting in some producers throwing away or burning raw fiber directly after shearing. Additionally, rural fiber producers often feel isolated and out on their own, without a support network in which to connect with fellow fiber producers in their area and establish markets that fit with or is fair to their price point.

What are the desired outcomes of this project?

There are four outcomes of this project. First, we will encourage and empower producers within our Fibershed to work together as a community in collaboration, supporting each other in the marketing and growing of the market for local fiber in ways and terms that best fit the needs of each individual farm as well as the overall community. Second, we will help local producers establish foundational avenues to venues that are appropriate for fiber being sold at the optimal price point. Third, we will assist producers in determining what farming practices are adding value and how to maximize it; by offering resources to connect to a local producer support system, producers can realistically adjust goals. And finally, our project will catalyze our long-term outcome of building a local fiber community that is making a profit off of their fiber products while simultaneously building nutrient dense soils on their farms through sustainable and regenerative grazing practices.

How can I sign up?

If you are interested in participating in these workshops as well as the one-on-one farm visit with our Producer Outreach Coordinator, sign-up for the first workshop can be found here. After registering for the workshop, we ask that you fill out the basic demographic survey, found here. If you have any other questions, feel free to contact us at threeriversfibershed@gmail.com.