About The Layzee farmer

How did you get into farming and shepherding, what was your path to this moment now? I started my farm so I had more space to raise food, while enjoying the outdoors and a place to raise animals. I was the kid that begged to keep stray dogs and cats.

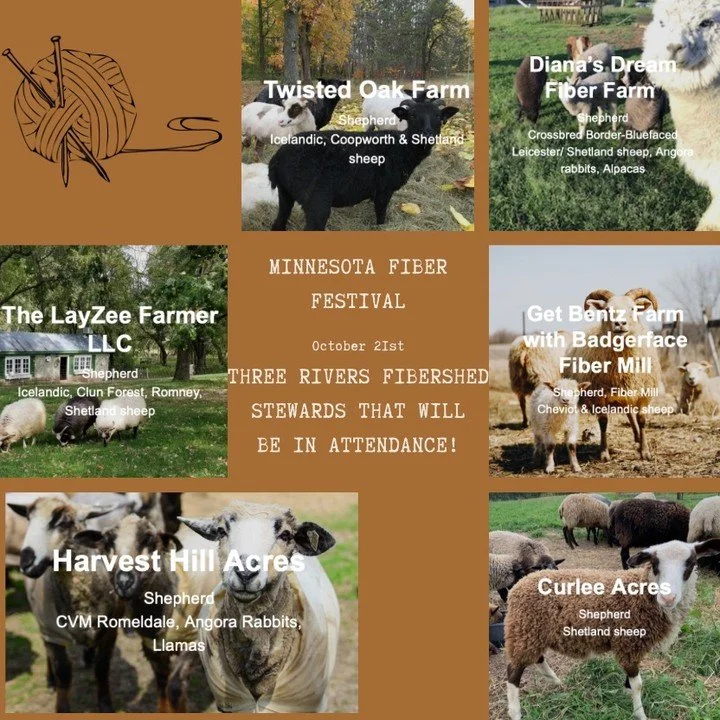

I choose to raise heritage breed sheep, specifically Icelandic because they can live on quality forage without the need for grain. I didn't know anything about fiber until after I bought them. As I met fiber enthusiasts I discovered the many facets of the fiber world and added additional heritage breed sheep to my flock. Fast forward 10 years...I have 4 separate breeds of sheep Icelandic, Shetland, Romney and Clun Forest. Each breed has the ability to thrive on pasture and provides very different qualities in their fiber.

How did you choose the breed of sheep to work with Bearcub Designs? I approached Diane about designing a pattern for my flock. She chose Clun Forest for her design.

What is something unique and exciting about your breed of fiber animal you chose for this project? Clun Forest are part of the Livestock Conservancy list as a threatened breed. The fiber is down like, does not wet felt, holds it shape and holds up as outerwear. I describe it as a workhorse fiber. Diane asked me to use natural dyes for the complementary color in the pattern. I have always incorporated flowers in my vegetable garden and have several varieties available to dye with. I don't think I'll ever get tired of working g with wool and creating.

Where can folks find kits and more supplies from your herd? I will have a limited numbrt kits at the Minnesota Fiber Festival in Cambridge. For those who spin and dye I will have Clun Forest roving with me too.

The pictures below are of Jennifer’s Clun Forest Sheep, the yarn and the projects that the two stewards collaborated on

About Bear Cub Design ( Diane pearsall)

Before I tell you about my ‘journey’ to become a knitwear designer, I’d like to address a more fundamental question: Why do I knit? In a world of disposable, throw-away goods, where so much happens online and isn’t real, knitting is my salvation; it is what grounds me. As Clara Parkes says, “ The rhythm of knitting is like the rhythm of breathing — calming, repetitive, and vital.” Knitting is real; I work with natural fibers that I can touch and cuddle as I inhale their earthy smell of sheep. They are my connection to the earth and the centuries-long traditions of producing clothing to cover and adorn our bodies. And traditional knitting styles and techniques connect me with women of the past, whose job it was to clothe their families, and often to produce the materials needed to do so. I have always been intrigued by the way that the garments they created were not only functional, but beautiful as well. Intricately patterned mittens, decorative bands on coats and skirts, and lace collars and cuffs were made for festive clothing. But everyday wear was also embellished, like the elaborate Peruvian mantas (square blankets) used as coats, and to carry babies, firewood, herbs, and other things. And they were made to last, and handed down to the next generation, and the next...

Tell us about your journey to become a knitwear designer.

I started knitting about 55 years ago, when I was in junior high school. Early on, I modified patterns to suit my vision of the project--what my friends call “dinking around”. They have often said that Diane can never follow a pattern, but always has to “dink” with it. I am a passionate “dinker”, and this led me to start designing while I was in high school. One of my first attempts (and thank goodness, no trace of it remains!) was a knitted patchwork mini skirt made with bright yellow, green, red and blue yarn--most likely acrylic, I’m afraid. From there it has been a wonderful trip down a wooly rabbit hole. I get an idea, and before you know it, the floor by my chair in the dining room is covered with books and yarn. Among my main organizing tools are dot-grid notebooks in which I write my patterns. I keep them on a shelf near at hand and consult them regularly.

Who has influenced your work and why?

Elizabeth Zimmerman has been the biggest influence on my life as a knitter. When I first discovered her book Knitting Around in 1985, I knew I had found a kindred spirit with a great sense of humor. I have all her books, and Knitting Workshop has a place of honor on my dining room bookshelf. It is probably the book I consult the most. The following two quotes sum up why EZ is so important to me as a knitter: “No two people knit alike, look alike, think alike; why should their projects be alike? Your sweater should be like your own favorite original recipes - like nobody else’s on earth. And a good thing too.” “Knit on with confidence and hope through all crises”. The other important influence has been my domestic partner, Owen. For over 40 years he has patiently looked at my projects and put up with my out-of-control stash. He is unfailingly honest and critical of my work with his attention to detail and great sense of color. We joke that my line is “why not?” and his is “why?” He has even taught me that sometimes it’s just better to frog the entire thing and start over. But he also doesn’t hesitate to let me know when he likes something.

Where do you find inspiration for your work?

I am a visual learner; I need to see something to understand it. So, I find my inspiration from images and pictures in books and magazines, and posts on Instagram and Pinterest, and my library on Ravelry. I also browse through digital collections from Estonia and other countries for ideas and motifs. I’m always buying knitting books and color cards and spend a lot of time gazing at them. At one point my favorite bedtime “reading”was the color card from Jamieson & Smith, handled so much that it had to be taped back together. I collect images and photos from Instagram and Pinterest to consult later. But I’m not interested in knitting, for example, the exact sweater in the Instagram post, but often just want to use a single motif or structural detail. I collect pictures of mittens (and sweaters) just to study the cuffs, or sweaters for the yoke colors and motifs. And many times one digital image leads me to another, and another, and another... I may start with picture of a mitten and end up deep into lace charts by Barbara Walker, or Guatemalan embroidery.

Favorite designers: Maja Karlsson, Elizabeth Zimmerman, Nina Granlund Sæther, and Beth Brown-Reinsel.

Three books that have influenced me greatly are Knitting Workshop (EZ), Knitting in the Old Way (Priscilla A. Gibson-Roberts and Deborah Robson), and the set called Estonian Knitting, published by Saara.

Favorite ”styles of knitting” and/or techniques: Anything Estonian or from Northern Europe; two-color stranded knitting, especially on small needles (US 2 or smaller); Estonian/Latvian braids; knitting from a chart rather than from written instructions; and more...

Walk us through the process, from inspiration to final product, when someone approaches you to work up a design for them.

I usually come at designing from one of two directions. The first is that I find a yarn that speaks to me, and I need to create something with it. And the yarn often lets me know what it wants to be. Thin, silky yarn might want to be a lace shawl or scarf. Rustic Icelandic fingering weight cries out to be patterned two-color mittens. Tweedy, speckled aran-weight wants to be a raglan cardigan. Or I find an image, photo, or motif that appeals, and I create something that includes it: a bird motif for a mitten cuff, for instance, or a circular Norwegian yoke that I can turn into a raglan sweater.

A good example of how I design step-by-step is the Clun Forest kits that I did for Jennifer Herbold of The Layzee Farmer, LLC.

In Spring of 2025, Jennifer, whom I had met a few times at knitting festivals, emailed me and said she wanted to talk about designing with her yarn. We spoke on the phone, and she asked me if I would design something for her new Clun Forest yarn that could perhaps be sold as kits at festivals in Fall 2025. She had recently added some Clun Forest sheep (an endangered breed) to her flock. When I asked her what she wanted me to work on, she said, “Your choice. I’ll send you some yarn and you can play with it.” It was an offer I couldn’t refuse--to play to my heart’s content with rustic, naturally dyed yarn (that she dyed!). A large box of yarn soon arrived, and off I went. Even though she gave me free rein, there were some parameters: a design that could be sold at a festival; something that would not take too much yarn and be too expensive for an “impulse” buy; an item that would use 2 colors, one dyed and one undyed; a pattern that would include some fun and interesting techniques, but not be too hard or time-consuming. Since cold weather would be coming, the obvious projects would be hats, mittens, scarves, and/or warm socks, maybe bed socks. I have designed a fair number of accessories, so I wasn’t starting from scratch, but I wanted to create something new, not just reuse an old design. Stranded knitting with two colors in the same round can be rather daunting for a lot of knitters, so I needed a technique to use two colors but without all the work. I decided that mosaic knitting was the new design element I wanted to include. So out came the books I have on the subject. I searched the internet (Instagram, Pinterest, and Google) for motifs and charts.

For the hat I found a vertical motif (three-in-one tweed) that would work nicely; I could decrease for the crown and not disrupt the pattern, which was important. I played around with different ideas for the brim. The first was two-colored ribbing with purl stitches to set it off from the body of the hat. But that looked too cluttered. So, I decided on a 2/1 ribbed brim in the dyed yarn for a good contrast to the vertical mosaic pattern. And a solid, chubby pompom of the same color as the brim tied the piece together. And, of course, the design had to be test-knitted to see if it would work. Several hats were completed and then frogged in the process. Designing is sometimes a ruthless endeavor, not for the faint-hearted; you need to be willing to knit a lot and then rip it out and start over. It can take several tries to get it right. But you learn something with each new attempt. Now, I had to find out if Jennifer liked the hat and wanted me to continue. Since she lives about 2 hours from me, I boxed it up and, with my heart in my mouth, entrusted it to the US Mail. It arrived safely, and she liked it. So, I was ready for the next step. I wrote up a preliminary version of the pattern, using the detailed notes I had taken in my dot-grid notebook as I worked. Over the years I’ve learned, sometimes the hard way, the importance of writing down every step of the process. This makes writing the pattern much easier. And the pattern is not just the written instructions and yardage needed. In my notes I include detailed explanations of the new techniques used, including graphics, links to video tutorials, and other images. The pattern should be as complete and self-explanatory as possible. (My thesis advisor in graduate school always said that one should write so clearly that even Martians would understand!) The next step was to have my test knitter replicate the hat using my pattern and the Clun Forest yarn. This is a vital part of the process, since I am too familiar with the pattern to see if it really works. The test knitter can offer valuable suggestions for improving the pattern and is quick to find problems and mistakes. And that left the final steps: making the kits and printing the patterns to accompany them and then posting the patterns for sale on Ravelry.

Done!

Does your personal style vary from that of your designs? No. I don’t think I would design anything that I wouldn’t wear.

Do you typically work with farm yarn? Or is this a first for you?

My tastes in yarn have evolved over the years from highly processed yarns to more rustic varieties that include locally milled undyed yarns (and those dyed with natural dyes), like those from The Layzee Farmer, Curlee Acres, Badgerface Fiber, and Twisted Oak Farmstead.

I knit with a lot of European yarn, the varieties that are more rustic and made from local, and often ancient, breeds. Some favorites include yarns from Selbu Spinneri in Norway, Trollenwol in the Netherlands, Ullcentrum in Sweden, Riihivilla in Finland (from a fabulous natural dyer, who unfortunately has retired). Two more commercial favorites are J&S jumper weight and Rauma Finullgarn (I have several bins of each, because, hey, you need a lot of colors to choose from). I seek out local yarns when I travel, and most recently have been adding rustic Estonian yarns to my stash, yarn from Kihnu, Muhu and Ruhnu islands. This summer I bought yarn practically out of the back of an SUV on Ruhnu, no labels or slick advertising, sold by the gram from the woman who raises the sheep. You ca'n’t get more local than that!

What is your favorite knitting accessory or tool?

My knitting needles.

If you could tell your customers one thing, what would it be?

Knit with natural fibers (and not yarn like '“superwash wool” that has been coated with plastic!). In this world where we are obsessed with health and what we put in our bodies, we should be just as concerned with what we put on them. Natural fibers are good for the planet, for your body, and most of all, for your soul.

For where to find Bear Cub Designs and the patterns that have been written using The Layzee Farmer Clun Forest yarn, search Raverly for Diane Pearsall or Bear Cub Designs